BHP will extend its partnership with the Centre for Ironmaking Materials Research (CIMR) at the University of Newcastle with a further A$10 million in funding to support ongoing research into decarbonising steelmaking.

The expanded research program will focus on low carbon iron and steelmaking using BHP’s iron ore and metallurgical coal, including conventional blast furnace ironmaking with the addition of hydrogen, and emerging alternative low carbon ironmaking technologies.

The collaboration, with funding from BHP’s US$400 million Climate Investment Program, will last five years and help train the next generation of PhD researchers and engineers.

In welcoming the funding, University of Newcastle Vice-Chancellor Professor Alex Zelinsky said the ongoing work of NIER would help drive the type of home-grown innovation needed for the world to decarbonise.

“With sustainability as a core focus, we are deeply committed to supporting research and innovation aimed at lowering our global carbon footprint,” said Professor Zelinsky.

“This continued partnership with BHP is a clear example of the University’s commitment to driving technological advancement through industry-engaged research, and we are pleased to continue with BHP’s legacy of innovation at our dedicated NIER precinct.

“A partnership of this kind – with both a rich history and a bright future – is evidence of our well-earned place as the No. 1 university in Australia for industry collaboration.”

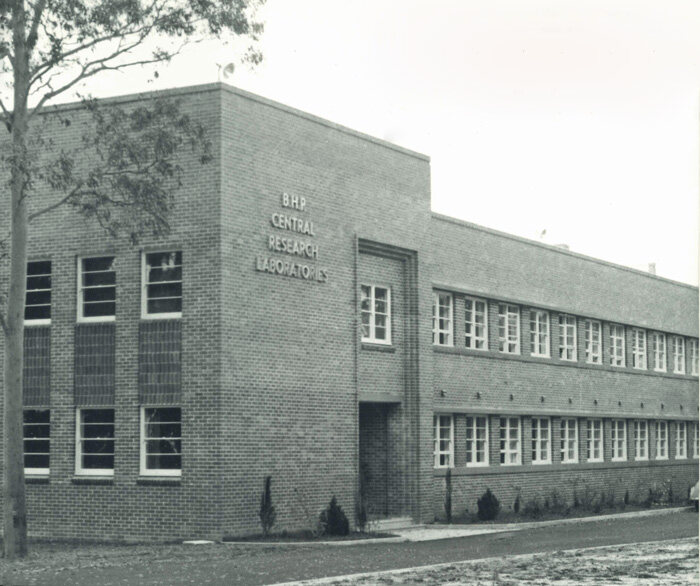

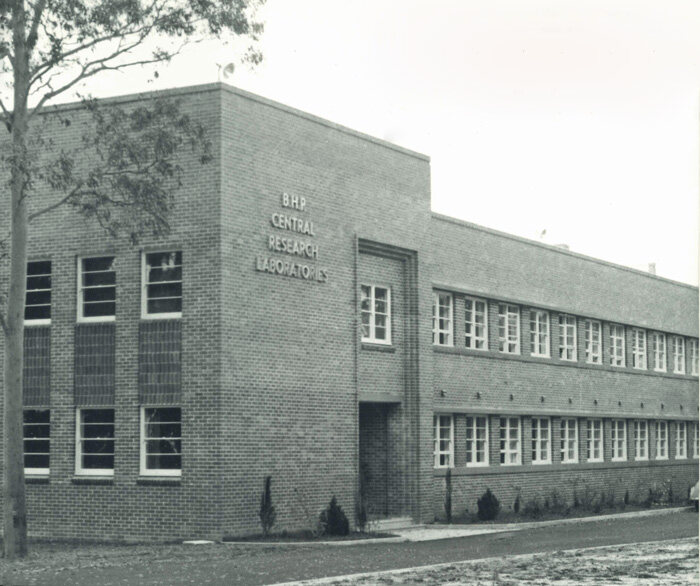

BHP has a long history with the city of Newcastle, and with the University of Newcastle dating back to commencement of collaborative iron and steel research in 1957. The establishment of the Newcastle Institute for Energy and Resources (NIER) in 2010 was another major step in BHP’s support for the local community and for steelmaking research.

CIMR was one of the first centres created at NIER, opening in 2010 to undertake ironmaking research supporting the use of BHP’s iron ore and metallurgical coal in the conventional steelmaking process.

A number of the current BHP Marketing team started their careers with the Newcastle Technology Centre, including Dr Rod Dukino, BHP VP Sales & Marketing Iron Ore, who said the type of research undertaken by NIER was vital to global efforts to reduce greenhouse gas emissions.

“Greenhouse gas emissions from steelmaking represent around 7-10 per cent of global total estimated emissions and the industry remains one of the most difficult sectors in the world to abate,” Dr Dukino said.

“Research and innovation have a critical role to play in accelerating the industry’s transition to a low carbon future. The expanded research program with the University of Newcastle complements BHP’s existing partnerships with our key steelmaking customers in China, Japan and South Korea.

“The expanded research program with the University of Newcastle complements BHP’s existing partnerships with our key steelmaking customers in China, Japan and South Korea. We are pursuing the long-term goal of net zero Scope 3 greenhouse gas emissions by 2050. Recognising the particular challenge of a net zero pathway for this hard-to-abate sector, we are continuing to partner with customers and others in the steel value chain to seek to accelerate the transition to carbon neutral steelmaking.”