Helping one of the world’s largest steel manufacturing companies to reduce their carbon emissions is all in a day’s work for researcher Rhiannon Chalmers-Brown.

As part of her PhD at the University of South Wales (USW), Rhiannon worked with TATA Steel to develop a biorefining process to take greenhouse gas emissions and convert them to chemicals for use in biopolymers and plastics.

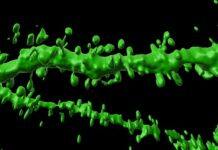

She has now built a pilot scale bioreactor, which is on site at the Port Talbot plant, to extract products from the gases – therefore capturing the carbon, instead of releasing it into the atmosphere.

“The steel industry is thought to be the world’s largest industrial contributor to atmospheric carbon dioxide, yet the British steel industry contributes approximately £9.5 billion to the UK economy every year,” said Rhiannon, who now works at USW’s Sustainable Environment Research Centre (SERC).

“Steel is a key material for the construction and delivery of renewable energy sources such as wind, hydroelectric and solar power, with the construction of one wind turbine requiring up to 230 tonnes of steel.

“It’s imperative that the steel manufacturing process is made more environmentally friendly whilst remaining cost effective and efficient, so that steel production becomes sustainable during the inevitable shift to green technology and enterprise.

“The bioreactor is now at pilot scale with the potential to develop into an affordable technology to bridge the gap between the steel industry as we know it, and a sustainable future in green steel manufacture.

“Working with TATA helped me to become familiar with the barriers facing large companies when trying to reduce their impact on the environment. TATA are proactive in their approach to finding solutions to huge problems such as carbon dioxide emissions, which made collaborating with them easy and enjoyable.

“I had so many fantastic opportunities and experiences, but a highlight for me was a full site tour from start to finish of the steel manufacturing process. It’s encouraging to know that companies do want to make these changes – the next big challenge is implementing them before it is too late.”

During her three-year PhD, Rhiannon got married, moved house twice, and taken on volunteering roles with Central Beacons Mountain Rescue and Women in STEM, as well as giving lectures at the Society of Engineering.

“If there’s an opportunity that comes my way, I make sure I take it,” she added.

“This research has been so rewarding and has opened up so many opportunities. I wanted my PhD to make a difference to our planet, and USW gave me a chance to do that.”