A flexible, 3D-printed device that could help physiotherapy patients exercise more effectively is being refined and tested at the University of Canterbury.

Stretchy and with built-in sensing capability, the interactive surfaces that act like fabric are being developed by Te Whare Wānanga o Waitaha | University of Canterbury (UC) Computer Science and Software Engineering Lecturer Dr Aluna Everitt.

She developed the original prototype during a research visit to Carleton University in Ottawa, Canada and is now exploring how it could be improved and potentially used in the physiotherapy and healthcare fields.

“There’s already been quite a bit of work in the digital wearables area and I’m keen to keep working on a new approach to the way this technology is designed and built,” Dr Everitt says.

“I’m hoping to create a device that can be easily worn on the body and even attached to clothing. I’m currently exploring how it can be applied to applications in the real world, and how it could track our bodies and the way they bend and move.

“Often people having physiotherapy will do their exercises correctly when they’re in the physio appointment but it can be difficult to keep doing them properly once they get home. This device might be able to help people perform their exercises correctly without the need for physio supervision.”

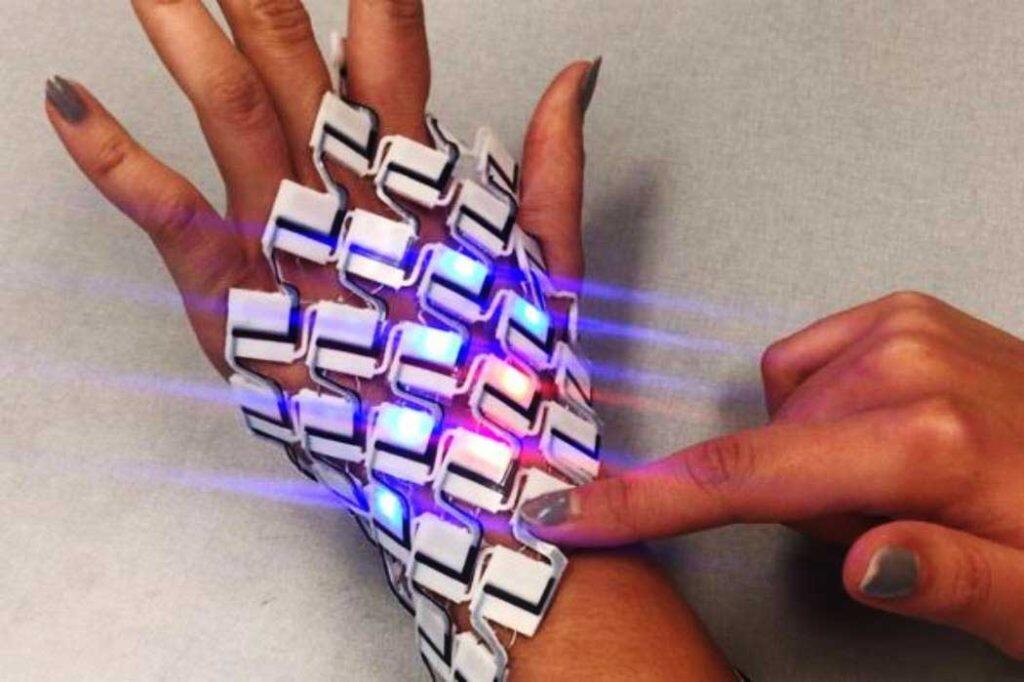

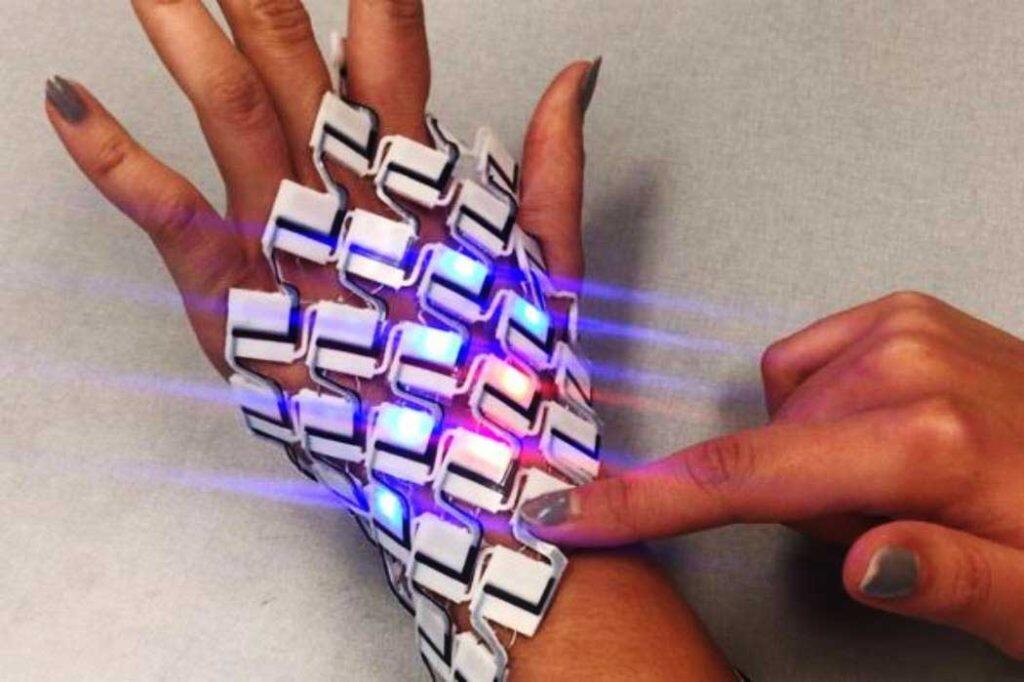

Created using a desktop multi-material 3D printer, the dynamic material is made up of small, connected 3D printed tiles and features interactive capabilities embedded during the printing process. Electronic components connected by conductive thread react to body shape and movement and can be customised to individual needs.

The digital fabric materials could be integrated into clothing, such as a knee strap. There are small LED lights with batteries that light up when they sense the correct angle and right amount of contact with human skin. Dr Everitt plans to use “haptic feedback”, or vibrations, from tiny motor discs embedded in the material, in her upcoming work.

Dr Everitt, who specialises in Human Computer Interaction, was a researcher at a number of universities across the United Kingdom before joining the University of Canterbury, including the University of Oxford, the University of Bristol and Lancaster University where she completed her PhD.

“My research focus is on democratising design and developing emerging technologies such as wearables, robotics, and tangible user interfaces so that it’s cheap, simple and accessible to build and test them,” she says.

“My multi-material 3D printing approach focuses on an affordable and accessible fabrication process that does not require highly technical or expensive tools and components.”

Dr Everitt collaborated with Alexander Keith Eady and Professor Audrey Girouard at Carleton University on her prototype device. The work was supported and funded by the National Sciences and Engineering Research Council of Canada and Amazon Web Services.

She is currently applying for New Zealand funding to continue work on the project with a focus on digital health applications. She is looking for PhD students to join a University of Canterbury research group she is setting up.