Researchers are working to address the environmental impact of medicinal cannabis waste. The results could have a big impact on the industry.

University of Auckland researchers have found a sustainable solution to help tackle the medicinal cannabis industry’s waste problem.

In collaboration with South Island-based producer Greenlab, and support from Callaghan Innovation, the researchers are developing processes that will help protect the environment by transforming cannabis waste into valuable resources such as biofertiliser.

The process involves destroying active cannabinoids from the waste and then turning the material into solid or liquid fertiliser that can be used to help grow new cannabis plants.

The collaboration could put New Zealand at the global forefront of the medicinal cannabis industry’s waste management, says research lead Associate Professor Saeid Baroutian, Director of the Circular Innovations (CIRCUIT) Research Centre in the Faculty of Engineering and co-director of Ngā Ara Whetū: Centre for Climate, Biodiversity and Society.

“It’s a perfect example of bringing the circular economy to the medicinal cannabis sector.

“Instead of the current linear ‘take-make-dispose’ system, our technology will connect productivity for the sector with environmental, social, legal and cultural acceptability. That is a big step towards true sustainability.”

Medicinal cannabis is one of the fastest growing industries around the world with a forecasted value of US$46 billion by 2026. In Aotearoa New Zealand, there is potential to generate exports comparable to kiwifruit in value.

But with this growth comes the challenge of managing medicinal cannabis waste, which includes unused plant matter, cultivation trimmings, discarded extraction chemicals and trashed testing samples. There is currently no specific infrastructure available to deal with cannabis waste and most, as happens overseas, ends up in landfills.

“This adds to the more than one million tonnes of organic waste already disposed of each year in New Zealand landfills,” says Baroutian.

“The problem here is not only the release of methane, a greenhouse gas more potent than carbon dioxide and a major contributor to global warming. Sending organic waste to landfills also means valuable resources are lost and cannot be effectively reused in the economy.”

With the industry in New Zealand still getting established, there is no public data available yet on the amount of waste being produced. In Canada, where cannabis markets are more established, it is estimated that more than 150 million tonnes of cannabis waste is generated each year.

For commercial medicinal cannabis operations, waste management is unique and complex, says Baroutian.

“The plant has unique qualities and, as an illegal drug outside of its medicinal use, there are strict Government controls over waste handling. Cultivators must record every gram of discarded material by tagging, tracking and tracing the waste from origin to final disposal.”

“This means that in addition to separating hazardous from non-hazardous waste, techniques used must render all waste beyond recognition and account meticulously for every scrap so producers can maintain their licence.”

The process works by mixing cannabis waste with water and then heating it to high temperatures. The high pressure and heat cause a chemical reaction that breaks down the waste into simpler and safer substances. All cannabinoids such as THC and CBD, the psychoactive compounds in cannabis, are destroyed during this process.

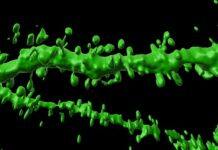

Under high temperature and pressure, the material in cannabis plants go through a chemical transformation process that converts the wet plant waste into a dark, crumbly and dry substance that looks like charcoal. This solid product is called “hydrochar” but unlike charcoal or coal, it is not harmful to the environment. It’s carbon and nutrient-rich and can be added to soil to improve fertility and water retention for better cannabis plant growth.

The liquid product from the process is also rich in solubilised carbon and valuable nutrients like nitrogen, phosphorus, and potassium, which can be recovered and used as a biofertiliser to help cannabis plants grow healthier and faster.

The next step is to develop a solution for its widespread use.

Current methods for cannabis waste disposal include biological treatment (composting and anaerobic digestion, which involves breaking down the waste into simpler compounds using bacteria and other microorganisms) or incineration (burning waste at very high temperatures until it turns into ashes), but both options have challenges. Incineration, while effective, is prohibited in New Zealand under the National Environmental Standards for Air Quality due to the formation of toxic gases and particulate matter.

“Composting and anaerobic digestion of cannabis waste can only occur at an approved facility with suitable systems to control odours from the process and deal with the leachate and digestate,” explains Dr Rupinder Brar, Greenlab’s Director of Cultivation & Resource Recovery.

“Although this is an approved method of disposal, there is no scientific evidence on the fate of cannabinoids in the composting or anaerobic digestion process.”